Additive 3D printing

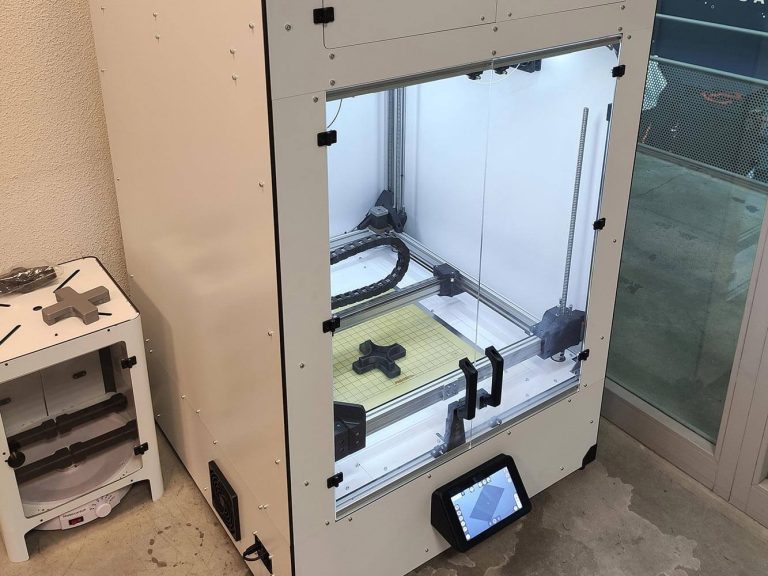

The emergence in the last few years of the revolutionary additive 3D printing process means we can now make prototypes or small runs in a wide variety of materials at a very moderate cost.

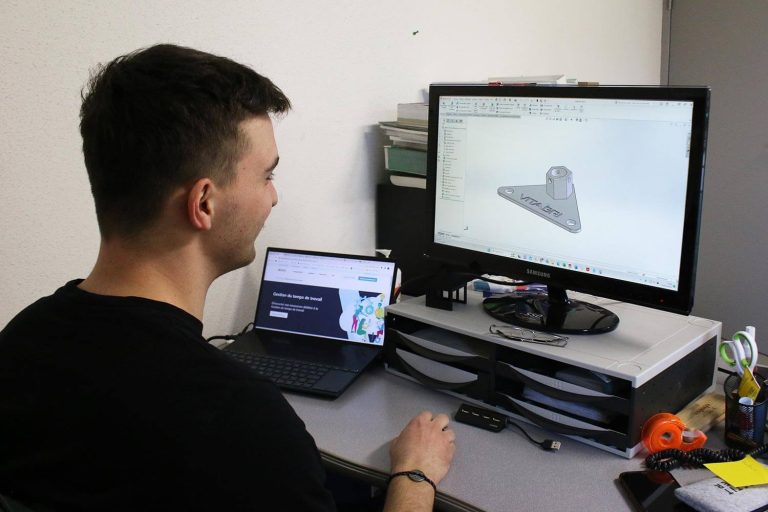

VITABRI has chosen to equip its design department with a French-made latest generation additive 3D printer. This technology allows us to produce plastic or stainless steel parts with characteristics close to those of injection-moulded or machined parts.

Fast execution, flexibility of use, a wide range of printing materials – 3D printing has revolutionised the way we work, allowing us to work faster and more efficiently. VITABRI has chosen to invest in this technology and to train its staff to give them an added area of expertise, which they can use to better serve our customers by developing new products or producing prototypes or small runs.